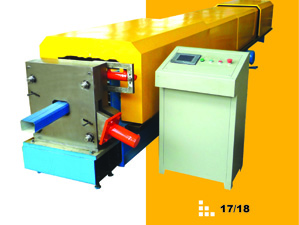

Precision Engineering

Our roll forming machines are meticulously designed for exceptional accuracy, reliability, and efficiency, ensuring seamless production.

Custom Solutions

We tailor every machine to your specific shape, size, and material requirements, providing a perfect fit for your manufacturing needs.

Cutting-Edge Technology

Stay ahead with our advanced R&D innovations, guaranteeing high-quality output and enhanced productivity.

Durability & Performance

Built to withstand demanding industrial environments, our machines offer long-term reliability and minimal downtime.

Comprehensive Support

From installation to maintenance and troubleshooting, our expert team ensures your machine operates at peak performance.

Proven Quality & Expertise

With years of industry experience, Hai Roll Fone delivers top-tier roll forming machines trusted by manufacturers worldwide.

Hai Roll Fone is a leading roll forming machine manufacturer in China, recognized for its advanced technology and high-quality production. The company offers a diverse range of roll forming machines tailored to different industries, covering everything from purlins and sheet panels to portable roll forming machines designed for on-site production.

One of Hai Roll Fone’s key strengths lies in its focus on innovation and customization. The company specializes in designing compact roll forming machines for customers with limited space and portable metal roof roll forming machines for efficient on-site panel manufacturing.

With a strong commitment to quality and reliability, Hai Roll Fone continues to push the boundaries of roll forming technology, ensuring that customers receive cutting-edge solutions that enhance production efficiency and meet their specific requirements. If you’re looking for a trusted roll forming machine manufacturer in China, Hai Roll Fone is your ideal partner.

Applications of Roll Forming

Construction Industry

Roofing & Wall Panels – Produces durable metal sheets and siding panels for buildings.

Structural Components – Forms purlins, beams, and studs for strong frameworks.

Rain Gutters & Ridge Caps – Creates custom drainage and roofing elements.

Electrical & Utility Industry

Cable Trays & Conduits – Ensures precise, uniform wiring supports.

Enclosures & Panels – Manufactures switchgear housings and cabinets.

Automotive & Transportation

Chassis & Structural Parts – Produces door frames, rails, and beams.

Exhaust & Underbody Components – Forms pipes, brackets, and shields.

Storage & Racking Systems

Industrial Shelving & Racks – Builds strong storage solutions.

Metal Planks & Walkways – Creates sturdy flooring for scaffolding.

Energy & Solar Industry

Solar Panel Mounting Systems – Manufactures lightweight, durable frames.

HVAC & Appliance Manufacturing

Ducts & Ventilation Systems – Produces precisely shaped air ducts.

Refrigeration & Commercial Equipment – Forms reinforced appliance panels.

Latest News

FAQ

About Us

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Aenean egestas magna at porttitor vehicula nullam augue.