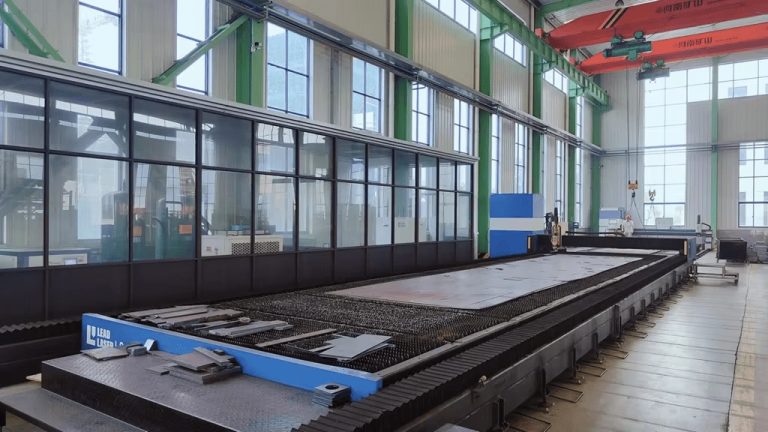

Facia board Forming Machine

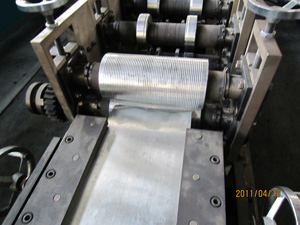

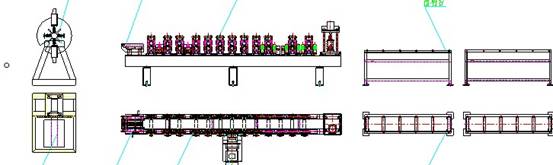

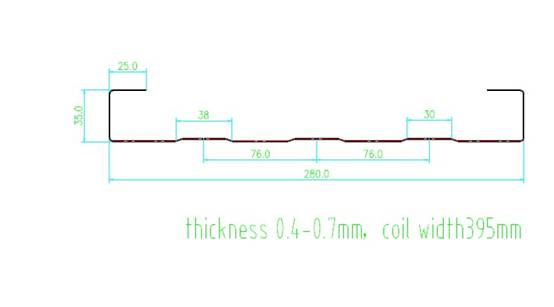

The Facia Board Forming Machine is engineered to produce high-quality fascia boards with precision and efficiency. Capable of processing materials with a thickness ranging from 0.4 to 0.8 mm and a strength of G350Mpa, this machine operates at a forming speed of 12 to 18 meters per minute. It features 12 roll stations, driven by a 5.5 kW main motor and supported by a 3 kW hydraulic power unit. The system is controlled via a PLC from reputable brands such as Panasonic, Omron, Siemens, or Mitsubishi, ensuring reliable and user-friendly operation. The chain drive mechanism and a 5-ton manual decoiler (with an optional coil car) facilitate smooth and continuous production.

Basic specification

| 1 | Material thickness | mm | 0.4—0.8mm G350Mpa |

| 2 | Forming speed | m/min | 12-18 |

| 3 | Roll station | stations | 12 |

| 4 | Main power | kw | 5.5 |

| 5 | Hydraulic power | kw | 3 |

| 6 | Control system | / | PLC panasonic/omron/simens/mitsubishi |

| 7 | Drive | / | Chain drive |

| 8 | Decoiler | 5T/manual decoiler ( coil car as option) |

Equipment:

3T manual decoiler,roll forming machine, hydraulic station, PLC cabinet, hydraulic shear,outables(2x2m)

Flow chart

Decoiler-feeding—forming–cutting-product-outables