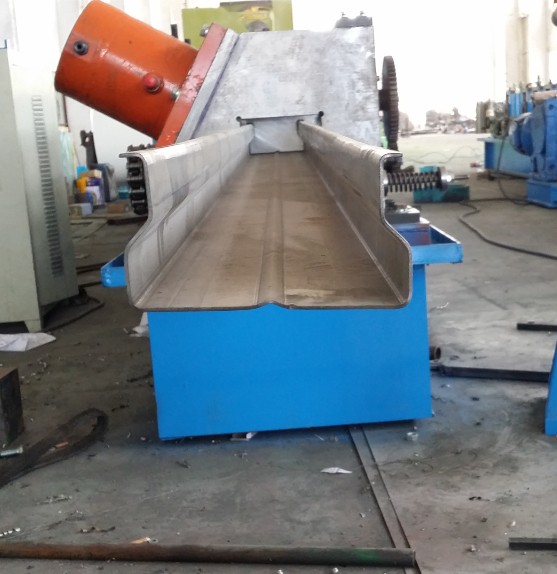

Upright Roll Forming Machine

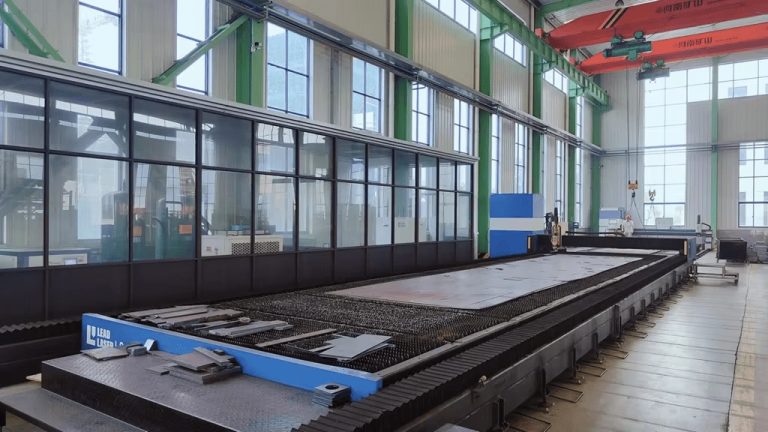

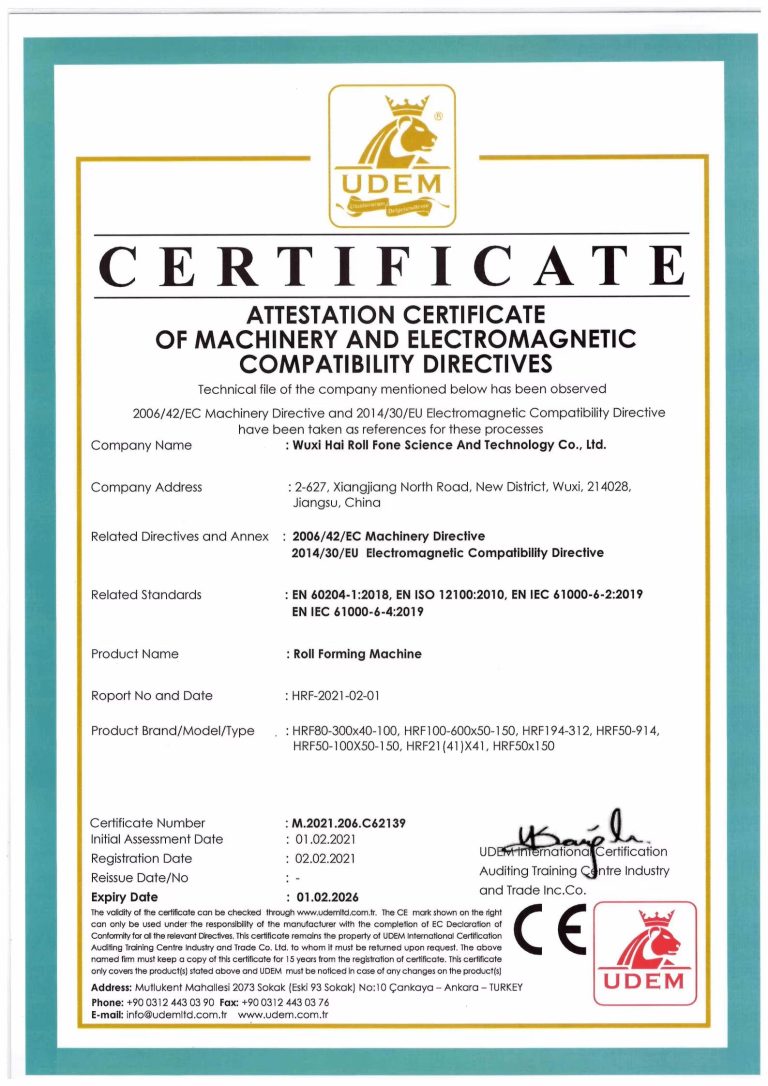

The Upright Roll Forming Machine is designed for producing high-quality wall panels. It features a motorized decoiler with a 3T capacity, a leveling machine with adjustable speed, and a NC300 servo motor feeder for smooth operation. With 19 forming stations and a hydraulic flying cutting system, it offers precision and efficiency in producing various panel types. The machine is equipped with a punching press, Cr12 punching molds, and high-quality steel components. It uses a PLC control system from Panasonic, Omron, Siemens, or Mitsubishi for easy operation.

Basic specification

| NO. | Name | Quant. | Remark |

|

1 |

Motoized decoiler |

1 |

Max 3T |

|

2 |

Leveling machine |

1 |

5.5kw frequency change driving-motor,speed adjustable |

|

3 |

Support frame |

2 |

Roller type |

|

4 |

NC300 servo motor Feeder |

1 |

1.5kw Yaskawa Servo motor drive |

|

5 |

Punching press |

1 |

80tons Capacity made in Yangli Group in china |

|

6 |

Punching mould |

1 set |

Cr12 |

|

7 |

Main forming Machine unit |

1set | Wall panel structure 19 forming stations |

|

8 |

Hydraulic flying cutting |

1 set |

|

|

9 |

Cutting blade |

2 sets |

Material Cr12,HCR58-62 |

|

10 |

Run-out table |

2pcs |

Steel frame with Rollers |

|

11 |

Electric panel |

1set |

PLC control system,Panasonic/Omron/Mitsubishi/Siemens |