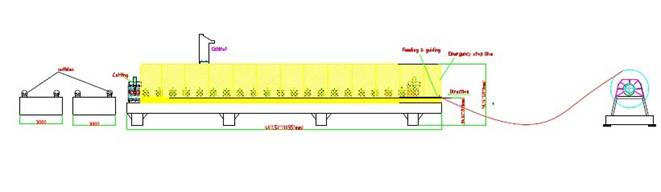

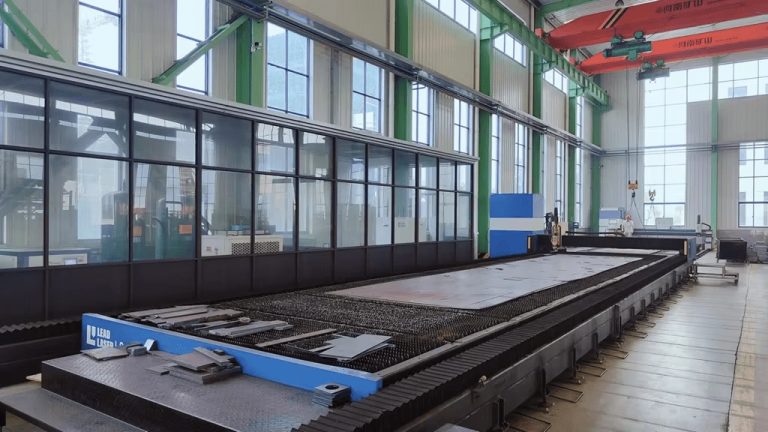

AG Panel Roll Forming Machine

- We adopt 20 roll forming stations with seperate stands structure and 11kw variable motor made in china .

- The machine can roll the steel thickness from 0.3mm up to 0.8mm,full hard pre-painted steel coils,galvanized steel coils and the speed can reach max 100ft( 30m/min)

- The rollers material is 45# steel,fine processment,hard chrome HRC48–52 .

- We adopt hydraulic stop-to-cut and cutting tolerance is +/-0.5mm

- We adopts PLC control,Mitsubishi,Panasonic made in Japana and Siemens made in Germany

- We us Yaskawa inverter speed control,Omron encoder measures the length made in Japan

- The safety covers on the machine is used to protect the operators

- Emergency stop press button is installed at the point where the cutting blades works and coils feeding entrance

Basic specification

| 1 | Material thickness | mm | 0.3-0.8mm Full hard,G550Mpa |

| 2 | Forming speed | m/min | 12-30 |

| 3 | Roll station | / | 20 |

| 4 | Main power | kw | 11 |

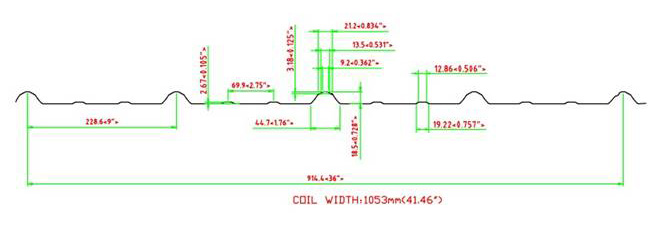

| 5 | Coil width input | 1053mm | |

| 6 | Hydraulic power | kw | 4 |

| 7 | Control system | / | PLC panasonic/omron/simens/mitsubishi |

| 8 | Drive | / | Chain drive |

| 9 | Decoiler | 5T | Manual type and hydraulic decoiler and coil car as options |

| 10 | Safety cover | Yellow color |