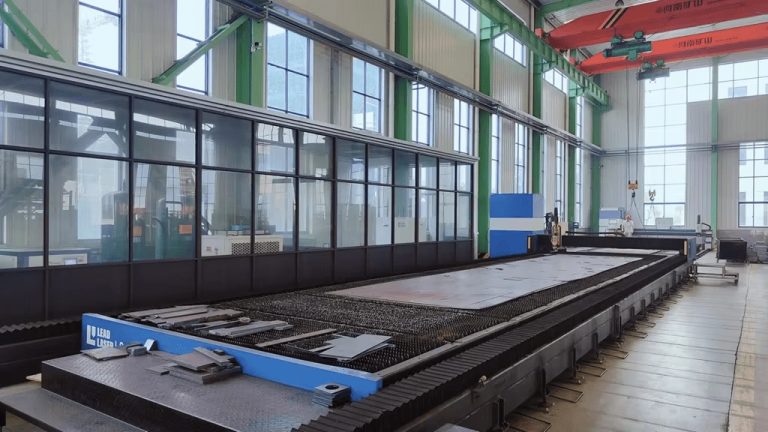

Box Panel Forming Machine

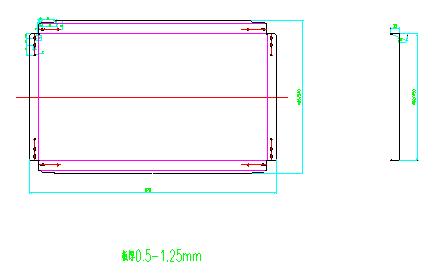

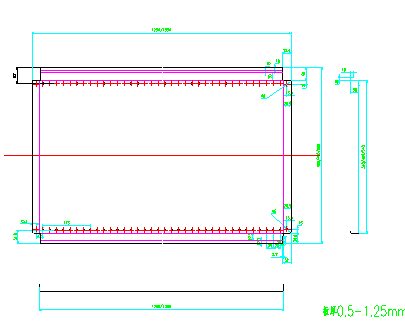

The Box Panel Forming Machine is designed for efficient production of box panels with a material thickness ranging from 0.15 to 1.25 mm. It features a robust 7.5 kW main motor and a 7.5 kW hydraulic power system. With 15 roll stations and a PLC control system from brands like Panasonic, Omron, Siemens, or Mitsubishi, it ensures precision and flexibility. The machine includes a 5-ton manual decoiler, side slitting unit, and hydraulic cutting and folding combinations, offering seamless operation for high-quality box panels.

Basic specification

Technology parameter:

| NO. | Items | Unit | Main specification |

| 1 | Material thickness | mm | 0.15-1.25 |

| 2 | Structure | / | Wall panel structure |

| 3 | Roll station | / | 15 stations |

| 4 | Main power | kw | 7.5 |

| 5 | Hydraulic power | kw | 7.5 |

| 6 | Control system | / | PLCpanasonic/omron/simens/mitsubishi |

| 7 | Drive | / | Chain drive |

| 8 | Decoiler | 5T | Manual |

Equipment:

5 tons manual decoiler, 1 set

Side slitting unit ,1set

Side waste recoiler ,1 set

roll forming machine, 1 set(including the corner cut and holes punching moulds)

Hydraulic cutting and folding combination

PLC cabinet, 1 set

hydraulic station, 1 set

output table(2m/each X2pcs )

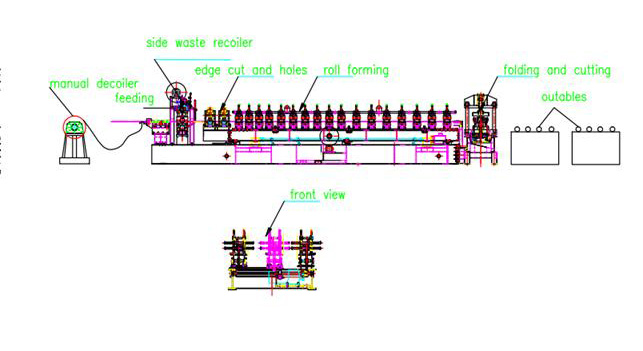

Flow chart

manual decoiler–feeding–2pinch rolls–slitting—corner cut& holes punching —roll forming—-hydraulic cutting&folding combination-outables