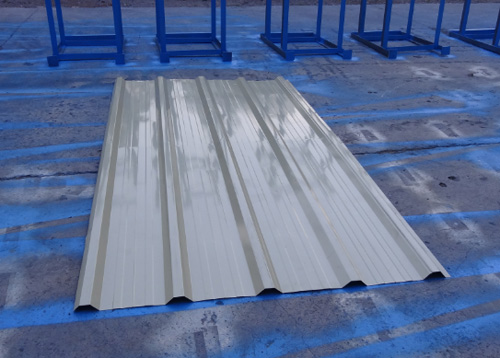

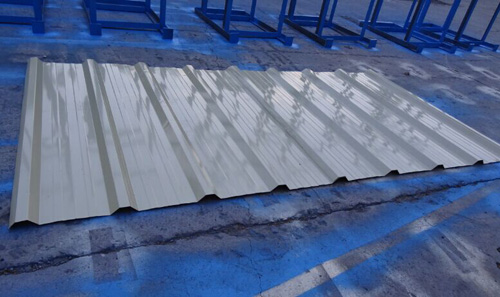

Double Layer forming machine

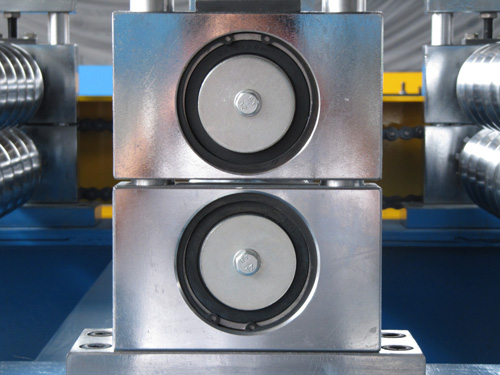

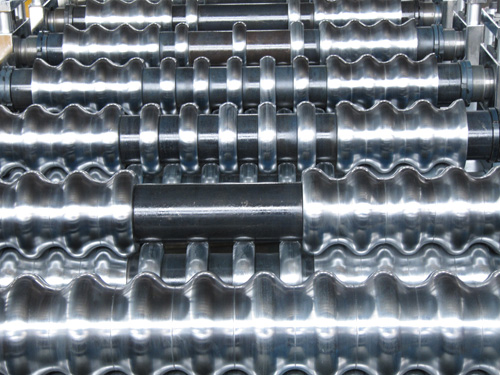

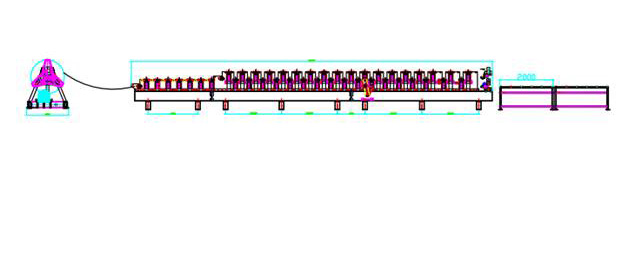

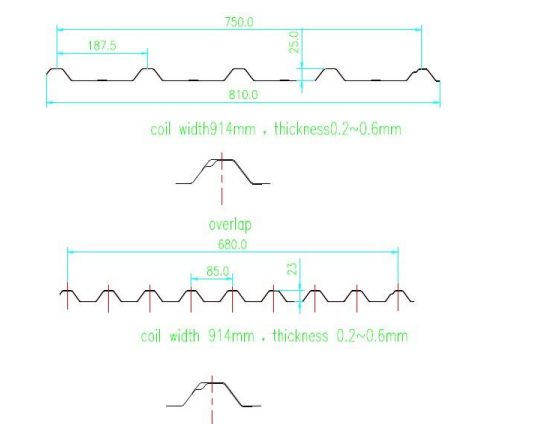

The double layer forming machine is consist of top layer and bottom layer and the both layers can share the same motor,PLC control cabinet,hydraulic control system but each layer has independent driving system

The biggest advantage for the double layer forming machine is to save the space and the budget,especially for the customers who has limited market and lack funds.

It is easy to shift from top layer into bottom layer for the operator and can achieve the productivity demands by adopting one single machine instead of the two independent machines.

Basic specification

| NO. | Items | Unit | Main specification |

| 1 | Material thickness | mm | 0.2-0.5m |

| 2 | Forming speed | m/min | 12–18 |

| 3 | Forming station | / | 18stations for top layer 23 stations for bottom layer |

| 4 | Main power | kw | 11 |

| 5 | Hydraulic power | kw | 4 |

| 6 | Control system | / | PLC panasonic/Mitsubishi |

| 7 | Drive | / | by chain |

| 8 | Way of decoiler | 5T manual decoiler 5T hydraulic decoiler as an option |